Project Zero Delta

Project ZeroDelta's goal is to algorithmically compare and classify points between the 3D models and their real-world, or point cloud, counterparts. This helps engineers quickly find where the model needs edited faster, where reality doesn't line up with the planned model, and track construction progress.

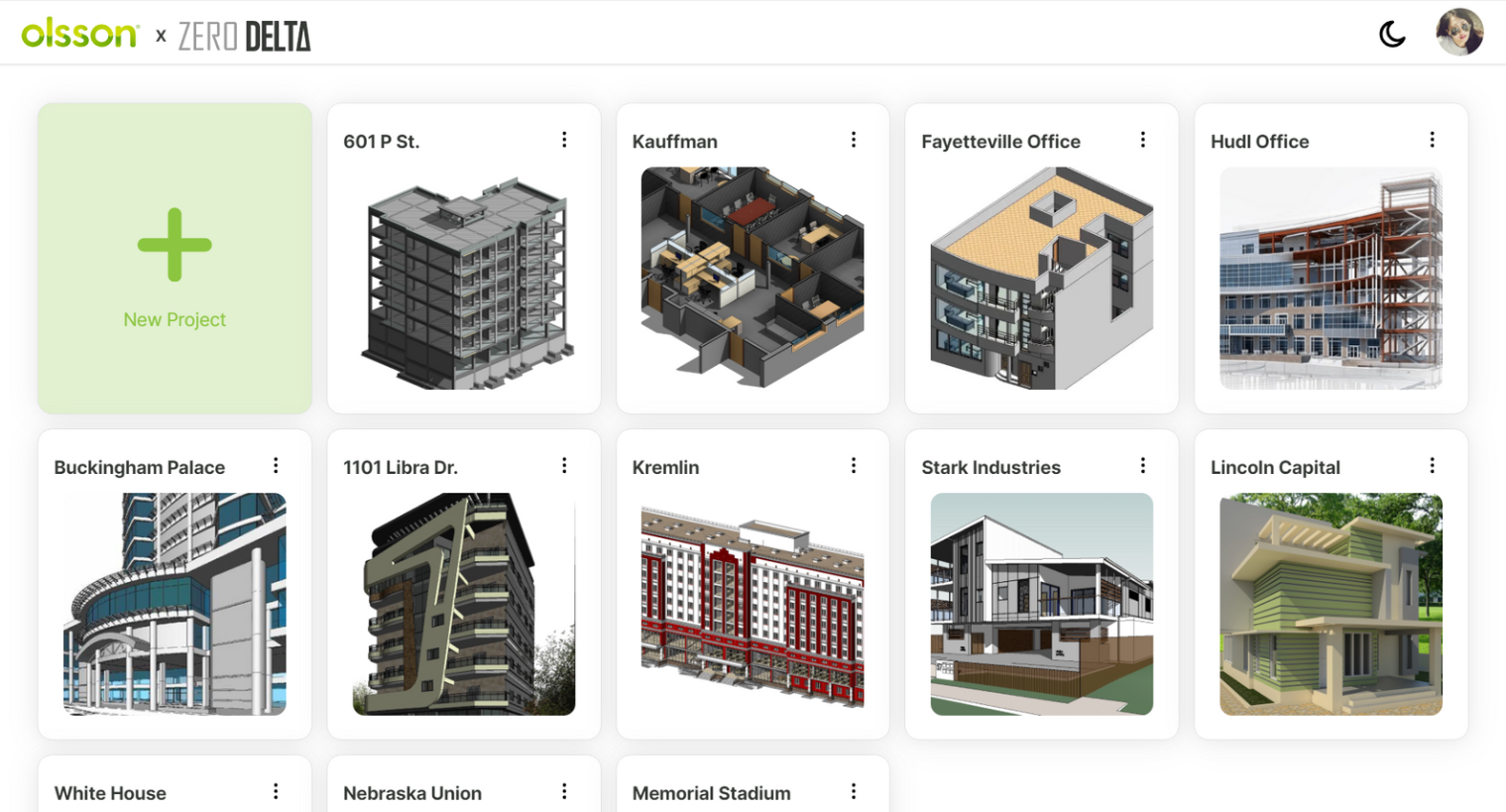

The Design Studio re-designed a previous algorithm to increase performce in both speed and accurancy of comparions. The team also built a web viewer where Olsson can upload models and point clouds to see the results of the comparison. Lastly, the team successfully migrated the project from only running on a local computer to running on cloud infrastructure.

From a system architecture standpoint, each model and point cloud is "chunked" into smaller pieces that match up with one another. Each pair is uploaded to a serverless function instance where the comparison is done, then all the accuracy scores and the models are stitched back together. This essentially allows for parallel computing. The larger the model, the more chunks are created and the more instances of the comparison algorith will be spun up. Once the model is compared, it is displayed using a viewer built on top of Autodesk Forge.

Technologies Used

Key Challenges

Managing multi-gigabyte data uploads for 3D models and point clouds

Implementing efficient data chunking for parallel processing

Handling large data types and processing in cloud infrastructure

Optimizing data visualization for large-scale 3D model comparisons

Ensuring accurate data stitching after parallel processing

Outcomes & Impact

Automated the model comparison process, eliminating manual work for engineers

Achieved exponential performance improvements from proof of concept to final implementation

Successfully migrated to cloud infrastructure enabling model sharing and collaboration

Enabled engineers to quickly identify and address model discrepancies

Reduced comparison time from days to hours through parallel processing